If you're manufacturing a product that requires multiple materials or enhanced durability, two advanced molding techniques often come into play: two-shot molding and overmolding. While these processes may sound similar—and even achieve comparable outcomes—they differ significantly in how they’re executed and when they’re best used.

In this guide, we’ll break down the basics of two-shot molding and overmolding, highlight their benefits, and help you determine which method is best suited for your next project.

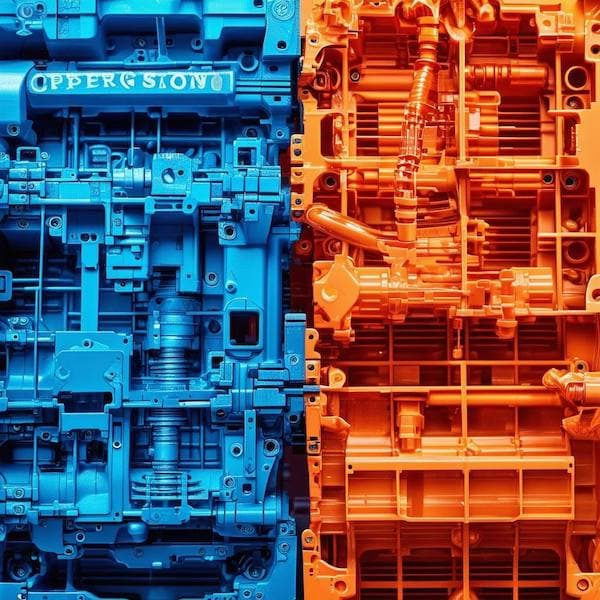

What is Two-Shot Molding?

Two-shot molding, also known as dual-shot or multi-shot molding, is an advanced injection molding process that uses two different materials or colors in a single mold cycle. These materials are injected sequentially into a mold to form a single, multi-material component—without requiring separate production steps or secondary operations.

This process is ideal for high-volume production of complex parts where precision, aesthetics, and performance are key.

How Two-Shot Molding Works

The process begins with the first material being injected into a mold to create the base component. Once this material has solidified slightly, the mold rotates or shifts (depending on the machine) to align a second cavity. Then, the second material is injected directly over or alongside the first material, bonding together to create a single, integrated part.

This method is highly automated, offering precision and consistency, especially important for industries such as medical, baby products, or high-end consumer products.

Key Advantages of Two-Shot Molding

Two-shot molding offers several benefits, particularly in high-performance and consumer-facing applications:

- Stronger Bond Between Materials: Because materials are injected in quick succession, the chemical and mechanical bond between them is typically stronger than with traditional assembly methods.

- Improved Efficiency: Eliminates secondary operations, reducing labor and cycle time.

- Enhanced Product Design: Enables the integration of soft-touch features, color contrasts, or functional zones (such as seals or grips) directly into the part.

- Cost-Effective for High Volumes: Ideal for large production runs, as the upfront tooling cost is offset by long-term efficiency gains.

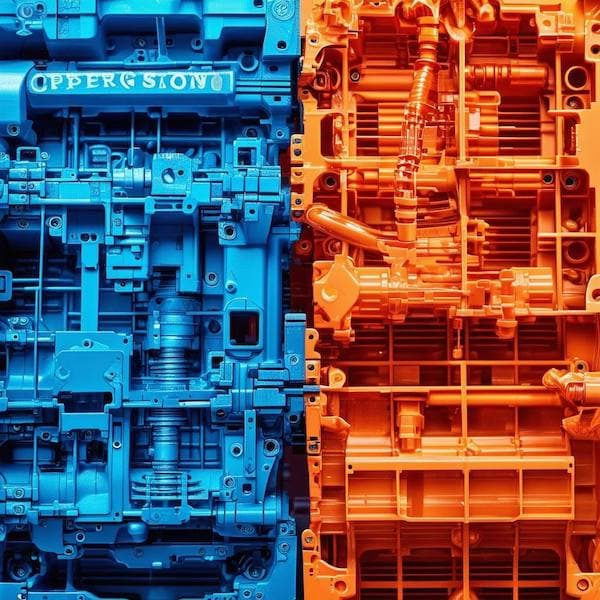

What is Overmolding?

Overmolding is a multi-step process where one material (typically a softer or elastomeric material) is molded over a previously molded part made from a different material. This technique is commonly used to add soft-touch grips, improve ergonomics, enhance chemical resistance, or increase shock absorption.

If you’d like to explore this topic further, be sure to read our dedicated guide on silicone overmolding.

Two-Shot Molding vs. Overmolding: Key Differences

Although both methods result in a multi-material product, the main difference lies in the process.

| Feature |

Two-Shot Molding |

Overmolding |

| Number of Shots |

Two materials injected in one continuous cycle |

Two separate molding operations |

| Tooling |

Requires specialized two-shot mold and machine |

Can use standard molds and machines |

| Material Bond |

Strong chemical/mechanical bond |

May rely on mechanical adhesion |

| Cycle Time |

Faster once set up |

Longer due to multiple steps |

| Cost Efficiency |

More cost-effective for high-volume runs |

Better for lower volumes or design flexibility |

| Design Complexity |

Ideal for high-precision, complex parts |

More flexible for varying designs or retrofitting parts |

When Should You Use Each?

Use Two-Shot Molding When:

- You need a high-strength bond between materials

- Your production volume is high enough to justify tooling investment

- You want to combine hard and soft materials in a single step

Use Overmolding When:

- You need design flexibility or are updating an existing part

- Production volume is lower or doesn’t justify the cost of two-shot tooling

- You want to add features to a part post-production

Which is More Cost-Effective: Two-Shot or Overmolding?

It depends on your production needs. Two-shot molding offers better long-term savings for high-volume, precision applications thanks to faster cycle times and less manual labor. However, overmolding provides more flexibility and is often more economical for low- to medium-volume runs or prototyping.

Choosing the Right Molding Process Starts with Understanding the Options

Before selecting a manufacturing partner, it’s important to understand the differences between molding processes. While both techniques allow for multi-material components, they differ significantly in terms of tooling, bonding strength, and cost efficiency.

At Extreme Molding, we specialize in silicone injection molding, helping companies in the consumer and healthcare markets produce safe, high-quality products. If you're exploring the best manufacturing approach for your next product, our team is here to help you evaluate your options and guide you toward the best fit for your goals.

Contact us today to speak with our molding experts.