The companies we work with to produce the highest quality goods possible within healthcare, consumer, and pet industries are often a testament to our processes and what you can expect from a manufacturer based in the USA during your injection molding project.

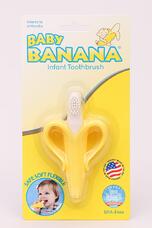

Here’s a look at the work we carried out with Live-Right on their Baby Banana Brush product to upscale their injection molding by contracting a second manufacturer in the USA, saving costs and maintaining the highest quality.

The Challenge

Originally produced in a factory in Taiwan, Live-Right approached us with Baby Banana Brush when they needed to find a second manufacturer to help their brand and business grow, and they were hoping to find one in the USA to compliment their overseas production process.

Baby Banana Brush had already established themselves as a unique, safer, and fun brand for toothbrushes and teethers that develop healthy habits at the earliest possible ages when they approached us and were looking to grow their reputation alongside production volumes.

As with many potential partners, Baby Banana Brush had some questions regarding the cost of production – would USA manufacturing be able to compete with overseas production and still create a product that exceeds expectations? The answer, of course, is that it can with the right manufacturer.

The Solution

The Baby Banana Brush product itself is made from the highest quality food grade silicone to ensure the product is non-toxic and BPA free.

Consumers expect safe products, the FDA requires it, and we consistently strive to exceed these standards with every single product we produce. In fact, we’re particularly well known for infant-friendly, pet-safe, medical and food-grade products within the silicone industry, so we were exactly suited to the needs of Live-Right.

We worked hard with Live-Right to solve initial mold challenges, being transparent in every adjustment and fix that we came up with during our process. Injection Molding projects can be complex, and they need to be adjusted to meet the requirements of products, so through constant communication we were able to deliver a product exactly as required.

The Result

Baby Banana Brush continues to grow today. As our time with Live-Right has matured so too has our relationship. We work at making sure our partnerships feel exactly like that – something both parties are full committed to and involved in. We both have the same goals when it comes to the end product, and that is extremely high-quality product that solves a challenged faced by many parents. As the product continues to perform well, and Live-Right grows we’ve been able to scale up production where needed.

As Ryan from Live-Right, LLC said: “Our companies have become so intertwined that Extreme sometimes feels like an extension of Live Right. We are thrilled to share our success with them and hope for many more years of a successful partnership.”

The Future

We’re always open to new and potential partnerships with clients hoping to grow their brand while maintaining their reputation for high quality silicone products. We have the ability to carry our technically-demanding medical silicone molding, plastic molding and overmolding in our New York facilities making us a unique facility particularly suited to healthcare and infant-friendly products. If you have a silicone product and you’re interested in scaling up production, contact us today for a free consultation. Our processes are transparent, and with over sixty combined years in business and industry our expertise runs deep.