Product designers, entrepreneurs, and inventors often ask Extreme Molding for material recommendations when manufacturing their products. With thermoplastic materials (plastics, resins, or polymers that are moldable above a specific temperature and then solidify when cool) there are countless choices out there and we often suggest enlisting the help of material suppliers as well as molders to figure this out.

Choosing the right material for your product can make a huge difference to your bottom line, as well as the quality of the product your manufacturer creates. Here are some basic guidelines your manufacturer should keep in mind and raise with you when choosing the correct plastic for your product.

Product Flexibility

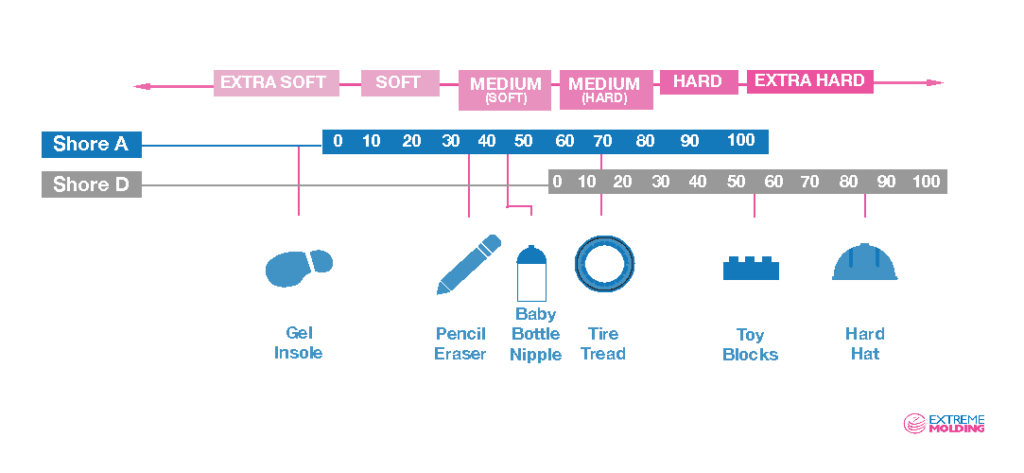

Most people think of plastics as fairly hard and rigid materials but they come in a wide range of flexibilities and hardness. Thermoplastics can technically fall into three hardness scales:

- Shore A: These are the most flexible and softest thermoplastics. Among these, thermoplastic elastomers (also known as TPE’s) are included. These are a common traditional rubber substitute, normally a mix of plastic and rubber.

- Shore D: Semi-rigid thermoplastics are ideal for when you want a product that can flex without breaking but is not completely hard. Polyethylenes and polypropylenes are good examples of plastics included in this category.

- Rockwell R: This is the hardest thermoplastics of the three, including Polystyrene, Nylon, Acrylics and Phenolics.

Choosing the right hardness for your thermoplastic product is going to come down its purpose. Shore A products can be great for soft mouse pads, rubber bands, and some silicone products, while shore D products can be used to make computer casings, book covers, and golf balls.

Service Temperature

Products have a wide range of temperatures they are used at and this requirement is important when selecting the appropriate plastic. Room temperature applications will do fine with most plastics and are often a good match for commodity materials such as polyethylene and polypropylenes, and acrylics. Most high-volume and low-cost resins have high-temperature versions that cost slightly more but extend performance an average of 50 degrees Fahrenheit. Engineered resins are required for high-temperature performance and are more expensive (for example ULTEMTM, Polyether ether ketone (PEEK) and fluoropolymers).

How Clear is your Product?

Resins come in a range of natural colors – most are translucent in their natural state but some other resins are tan. Colors are achieved by adding pigments to the natural resins. Polystyrene, Polycarbonate and the co-polyester material TritanTM are all high-clarity resins in their natural state. These high-clarity resins are all rigid and so are popular for use in products that need glass-like clarity, for example, water bottles.

Price Requirements

The prices of materials can vary widely, here are some common materials and their costs:

- Polyethylene and polypropylenes : Generally, around $1-$1.50 per pound dependent on the volume purchased.

- Polycarbonates and other commonly engineered materials: Cost in the range of $3.00 per pound.

- More specialized engineered resins: These can have prices up to $50 per pound.

A good rule of thumb is the more specialized and demanding the product requirements, the higher the material cost. In addition, the lower the weight of your material, the lower the material costs and the faster the cycle time.

Regulatory Requirements

These days it’s common for products to have regulatory requirements. At Extreme Molding, we make a range of products that are BPA-free, FDA-compliant and/or Class VI compliant to be used for food service, medical and baby products. If your product has regulatory requirements the materials you use will need to be specific and match those requirements

For example, BPA (Bisphenol A) is an industrial chemical used to make some plastics and epoxy resins. BPA-free products (such as microwavable containers and drinking bottles) are now commonly made from a replacement material known as TritanTM. Your manufacturer should be able to provide suitable materials to produce BPA free products using materials like TritanTM if you require this.

Products that come in contact with food or your consumers’ mouths should also be manufactured from FDA compliant materials (for food contact see 21 CFR 177.2600) and external body contact products must be made of USP Class VI compliant materials indicating biocompatibility.

There is a slight price premium for materials with FDA and Class VI compliance as compared to industrial-grade materials but your product won’t be viable for use in certain sectors without these compliances. As you might imagine, the major price premium is with implantable grade plastics.

Beyond the Basics

On top of all of this, your manufacturer will be thinking about the environment your product will be exposed to during use. An in-depth knowledge of chemical compatibility will ensure your product can weather the elements if required and withstand UV radiation if used outside. Most manufacturers should have expert understanding of these complex chemical interactions.

Coupled with an understanding of the durability and tear resistance of certain materials, their knowledge should steer the manufacturing process towards creating an efficient and high-quality product.

At Extreme Molding, we not only take joy in selecting materials perfectly suited for our clients, but we also have a deep understanding of the kinds of materials suited to each and every sector. We have a wide range of clients across many verticals including those in medical, animal, food, and baby industries.

You can read more testimonials from companies we are proud to work with here. For more information on our liquid silicone capabilities get in touch. Our managers have over 60+ years of combined business experience and our team are experts in manufacturing.